Research Phase 4

Manufacturer Independent Machine Transferability

Laser-based manufacturing processes are highly sensible to parameter changes. Therefore, finding suitable process parameters poses a time- and cost-consuming challenge to companies. Monetizing manufacturing data enables companies to open new income streams. However, these valuable process data require a secure transfer across company boundaries. In addition, the buyer company tends to have different laser machine technologies, requiring a parameter conversion to adopt the laser process to its new environment.

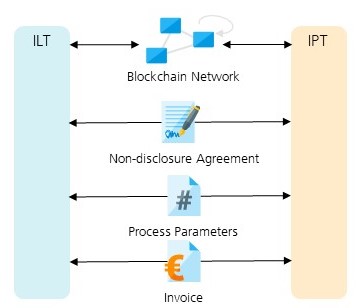

In this ICNAP-Research project, we built a permissioned blockchain network that enables a secure transfer between companies. We simulated a data transfer scenario between two companies, the Fraunhofer Institute of Production Technology IPT and Laser Technology ILT, representing two companies with a buy-sell interaction of process parameters. We considered the laser beam welding process as a test-case and handled its process data, like laser power and laser beam width. A process parameter conversion based on a numerical model was performed , before finally transfer-ring to the seller company. The implemented network also allows automatic processing of digital documents, like non-disclosure agreements or invoices, in a quick manner through smart contracts. This way, a highly automatized buy-sell process with document processing was established using a blockchain network.

Our implemented network utilizes the Hyperledger Fabric framework , an open-source project hosted by the Linux Foundation. It allows an efficient blockchain implementation where the consensus mechanism works on a voting-basis instead of a lottery-basis, the latter one requiring a lot of computation power, as in the case of the cryptocurrency Bitcoin. This consensus algorithm is used to maintain an agreement of ledger data on distributed ledger data. Smart contracts for the non-disclosure agreement, parameter transfer, and invoices were implemented and deployed on the nodes of the blockchain network. These are able to read and write to the common ledger data, thus enabling the complete scenario of buying/selling process parameters.

We have built a prototype blockchain network with smart contracts for our use case of transferring laser welding process data and an automatic document processing of non-disclosure agreements and invoices. The intrinsic data security aspects as well as a high level of automation of a blockchain are especially suitable for handling industrial data, where the use of digital twins and data analytics applications are steadily increasing.