About Us

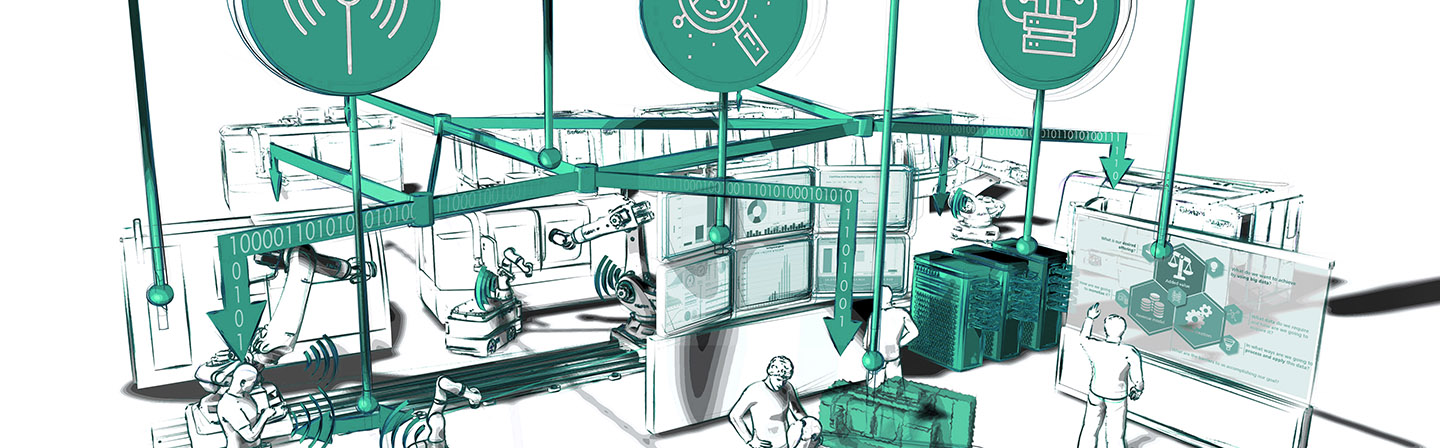

Meeting the challenges of digitalization and developing solutions for networked, adaptive production: that is the goal of The International Center for Networked, Adaptive Production (ICNAP), a renowned industry community and the three Aachen-based Fraunhofer Institutes for Production Technology IPT, for Laser Technology ILT and for Molecular Biology and Applied Ecology IME. Find out what defines our community, what services we offer to our partners and what specific topics we are working on.